QUICK TURNAROUND, HIGH QUALITY

Even your most challenging production demands are delivered on time and according to our high quality standards.

STATE-OF-THE ART EQUIPMENT

Offering a one-stop metal forming and metal fabrication shop with in-house toolmaking, the very latest technology and a skilled team.

ALWAYS CUSTOMER-FOCUSED

We work with you to provide solutions to your metal forming requirements. With a focus on the customer from start to finish.

ONE-STOP METAL FORMING AND FABRICATION

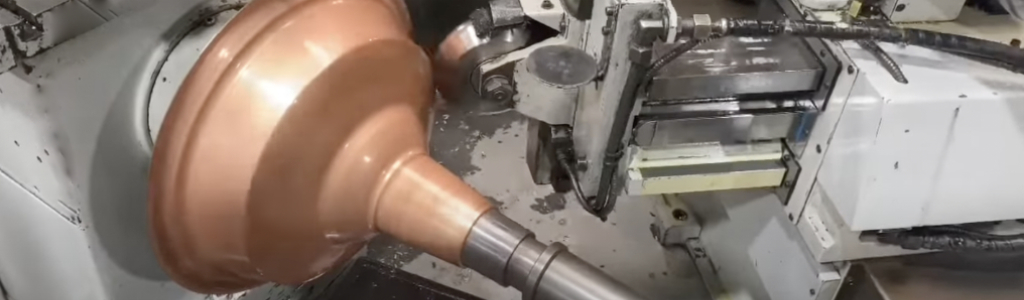

Fastest changeover CNC metal spinning with the Leifeld SC-310S offering unequalled performance unlimited power for short and long runs

One-stop metal forming and fabrication with in-house toolmaking, CNC metal spinning, automated metal sanding, CNC fibre optic laser cutting, CNC folding, CNC punching, CNC turning, deburring and edge rounding, CNC polishing, metal pressing, spot and MIG/TIG welding, component and full-product assembly.

Download our Capability Flyer

Client Testimonials

Don’t take our word for it – see what our clients say:

“Our clients are infrastructure companies working on major projects – roads, bridges and large commercial buildings – and they have stringen demands around quality. We were looking for a reliable supplier and Woodland Metal Spinning was recommended to us. The first batch they produced for us was perfect and every job since then. We’ve been working with Woodland for many years.”

Managing Director

Machining, fabrication and reverse engineering company servicing the resource and infrastructure sectors.

“Rod and the guys at Woodland have always been able to come up with effective solutions. Woodland has the machinery and the personnel, and they are able to turn around projects within a reasonable timeframe. Rod is very knowledgeable and easy to work with.”

Sales Director

Innovative engineering and manufacturing business.

“We work with Woodland Metal Spinning for the following reasons: they produce quality products, are excellent to deal with and have good lead times.”

Managing Director

Small business committed to manufacturing their unique product in Australia

“We have a long history with Woodland Metal Spinning spanning 38 years, and working with Woodland has always been a joy. The original owners supported us in the development of the tube-spinning machinery that forms the core of our business. More recently, Woodland implemented new spinnings in stainless steel for our state-of-the-art multiuse poles which can house lighting, 4G, 5G, CCTV and environmental monitoring services.”

Managing Director

Specialists in tubular products.

INNOVATIVE TECHNOLOGY

Investing in the future

Woodland Metal Spinning has been in business since 1937. The secret to our continuing success is innovation combined with skilled craftsmanship. We invest in the leading technology from around the world, so we can provide our customers with the quality and turnaround times they require. Read more

LEIFELD

German CNC metal spinning technology that is world’s best.

4kW ByStar Fibre Laser

Swiss precision from Bystronic offering fast turnaround, large capacity fibre optic laser cutting.

YAWEI PBS 110-3100

High-speed high-precision press brake for accurate bending.

TOOLMAKING

In-house toolmaking reduces costs and lead times.

Latest News

Read about developments at Woodland Metal Spinning and in the metal forming industry …

Introducing our 4kW Fibre Laser from Bystronic

Fibre optic laser cutting for faster more accurate cutting of mild steel, aluminium and stainless steel sheets 0.55mm–10mm and up to 3100mm x 1580mm. Plus deburring, edge rounding and CNC polishing for a flawless finished product.

Read moreVintage copper light shades

Classic industrial warehouse style light shades have made a recent resurgence as a stylish and unique lighting feature. The style was pretty much standard in any warehouse in the middle[…]

Read moreBring manufacturing back onshore

Our one-stop metal forming shop is open for business: Is it time to bring your manufacturing back home? The COVID-19 pandemic has highlighted the risks of over-reliance on off shore[…]

Read more